These are a few resources I have been looking at online which are fairly interesting with regards to the robe.

The bottom two links are for companies that sell civic robes, which is interesting to see the kinds of prices they charge.

http://www.georgianindex.net/coronation/Coronation-GeorgeIV.html

http://www.burgon.org.uk/society/library/biblio.php

http://www.nationaltrust.org.uk/hughenden-manor/things-to-see-and-do/ - national trust collections

http://www.shepherdandwoodward.co.uk/welcome.html

http://www.civicrobes.com/Pages/Contact/Contact.htm

Friday, 30 March 2012

Wednesday, 28 March 2012

Fabric Sourcing in Soho

|

| Samples from London |

I was looking for Scarlet red silk or lightweight wool, a white silk for lining the gown, black velvet ribbon - 3.5cm, 3.8cm, 4cm and 7.5cm in width and fur 11cm in width.

I went to the following shops when sourcing:

Barnett Lawson Trimmings, Little Portland Street

MacCulloch & Wallis, Dering Street

Borovick Fabrics, Berwick Street

The Cloth House, Berwick Street

The Silk Society, Berwick Street

The Berwick Street Cloth Shop, Berwick Street

and

Misan Textiles, Berwick Street

They were all very helpful with the project and advised me on the kind of fabrics they stocked and gave me samples. One assistant advised that sometimes if you put silk and silk together as a lining it can make the garment quite static and therefore I could use an anti static lining.

Furs

|

| MacCulloch and Wallis |

I didnt find as much fur as I wanted and a shopkeeper said that recently he had noticed that shops weren't stocking it as much as they used to.

MacCulloch and Wallis stocked faux furs 7.5cm and 14cm in width. The 14cm furs are £21+ VAT and I think the lower fur in the picture is a good colour for the robe.

|

| Barnett Lawson Trimmings |

In The Berwick Street Cloth Shop they sold this fur fabric that was 140cm wide for £69 a metre. I thought that an alternative would be to buy about 25cm of this fur and use is as a trimming, this would therefore be £17.25. I am not sure about this fur in particular though as the fur lies in lines and may not be suited to the gown.

|

| The Berwick Street Cloth Shop |

Black Velvet Trim

|

| Barnett Lawson Trimmings |

There are many different widths of velvet trimming on the Mayor's robes and I find all these quite difficult to source. 3.5cm, 3.8cm, 4cm and 7.5cm.

At Barnett Lawson they had these 2 wider trimmings. The one on the left of the photograph is 3.6cm wide, it has to be bought in 10 metre rolls which is £10.30+ VAT. On the right is a ribbon 7.2cm wide and is sold at £4.50 a metre

|

| MacCulloch and Wallis |

In MacCulloch and Wallis the widest velvet ribbons they stocked were 3.6cm and 5cm wide. The 3.6cm wide ribbon on the left is £2.55+ VAT whilst the 5cm ribbon in the middle of the photo is £3.50+ VAT.

As an alternative I got a sample of satin ribbon. I thought that satin ribbon might compliment a silk gown better that velvet ribbon, which can look quite heavy. This sample on the right is 7.5cm wide and £2.20+VAT.

Red Lightweight Fabrics

I got a variety of red fabrics from £6 - £69. On the toile we used 490cm of 140cm wide fabric, the pieces we cut had a 5cm seam allowance to allow for adjustments but to be safe we probably need about 5m of the top fabric. Therefore with a budget of £400 I have estimated that the top fabrics needs to be about £40 a metre but could be more if with less expensive fur for example.

I mainly got samples of silks because in the first meeting the Mayor preffered the fine imperial silks.

Some of the silks I got samples of are very lightweight

|

| Cloth House |

|

| MacCulloch and Wallis |

|

| Borovick Fabrics |

I am concerned that these samples are too lightweight. Some of them are similar to the weight of the toile we have made from lightweight calico. The toile is draping in a different way to the original garment and this is because of the fabric isn't heavy enough to hold the fabric straight. Therefore I think that maybe we should consider a silk that is a bit heavier. It would still be silk so it would be breathable and lighter than the wool but hopefully the weight would cause the fabric to hang well.

|

| The Silk Society |

The one on the left is quite a bit heavier and the red is a bit too dark for the robe. It is 140cm wide and £69 a metre.

The middle sample has quite a matt silk and is 140cm wide and £60 a metre.

The silk on the right is 112cm wide and £50 a metre. This has quite a velvety texture, which is quite a good weight and I think would be suitable for the robe.

|

| The Berwick Street Cloth Shop |

Both these silks from the Cloth Shop are £50 a metre each. The sample on the left is very matt in texture which I dont know would work well on this robe. The sample on the right is quite a heavy satin silk, it is nice and I think would work really well on the robe as the pleats would sit really nicely but I am not sure if it is light enough for the Mayor to regard it as a summer robe.

I also got samples of linens and cottons. These are a cheaper option but I don't think they have the glamour needed for a gown like the one we're making. Also some of the cottons have a looser weave that wouldn't be suitable.

Lining Fabric

|

| The Berwick Street Cloth Shop |

|

| MacCulloch and Wallis |

The sample from the Cloth Shop is a very nice silk, it is 140cm wide and £29 a metre. I like this cloth as you can not easily see the red underneath it and so would make an effective lining also it is nice and soft on the touch so would be pleasant to wear.

In MacCulloch and Wallis the assistant advised the Bremsilk Cupro lining which is on the right. This kind of lining is breathable, antistatic and a good quality. It is £8.33+ VAT and is an option to consider.

The other sample is silk habotai, it has a nice texture but is possibly too thin and fragile for the robe.

I am really pleased with the samples that I have got to take for first fitting. It is a good range to consider and I hope that with my previous samples and any that Abi has got that we have found our final fabrics. I would have liked to have gone to Shepherds Bush also to sample but unfortunately I couldn't fit it into the trip as I had to also visit museums and the theatre. I will definitely be visiting London again when I am back in Bournemouth and if we are not happy that we have found the right fabric for the robe I will source a lot more.

Museum of London

When doing research into what museums display Mayoral Gowns I came across the display in the City Gallery at the Museum of London, which I visited on a trip to London yesterday (27.03)

In the gallery there was a beautiful Lord Mayor's robe. It belonged to Walter Wilkin who was Lord Mayor of London from 1895-1896. It is incredibly decorative and is made of damask silk and gold. The Lord Mayors have many robes for different occasions, this one was an 'entertaining gown' worn on civic-state occasions when no royalty were present.

One of the main exhibits in the museum is the Lord Mayor's coach (pictured above). This coach was used in the annual procession the Lord Mayor takes from the City to the Palace of Westminster to swear allegiance to the monarch. Originally in the early 13th century until the 1420s the Lord Mayor and his Aldermen would have taken this journey by horseback and then by water on a float until 1857. Historically the route varied each year because it would pass through the elected Mayors ward and so sometimes it was necessary to go along the river on a barge or float. The coach was introduced in 1711 after the Lord Mayor Sir Gilbert Heathcote fell of his horse, this was originally a hired carriage until in 1757 Sir Charles Asgill persuaded the Aldermen to buy a new state coach, as he was going to be the next Lord Mayor.

| The 2009 Annual Lord Mayors Parade |

I hadn't realised this

tradition has continued throughout history. The robe that the Mayor is wearing

is a ceremonial gown and seems identical to the Mayor’s robe that we are

making.

Sunday, 25 March 2012

Patterns used

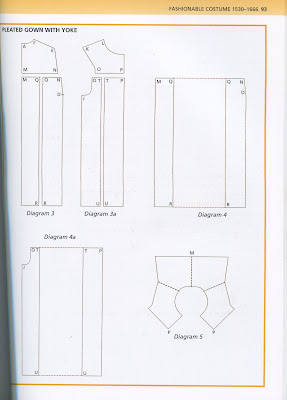

When pattern drafting the gown the only reference we had

were our notes on measurements and photographs.

We researched patterns that had been made of robes. This was

quite limiting, there was nothing I could find that had a similar sleeve. I did

find some patterns for medieval robes which were similar however.

I thought that the Turkish morning gown had a similar

construction to ours however it is very flared. It is interesting to see how

many variations of gowns and cloaks there are from medieval times.

This pattern by Janet Arnold is another that we looked at. It is similar in its use of fur and trimmings and that it has

pleats down the back. We used the shape of the armholes on this pattern to

inspire ours. This has a kind of hanging sleeve that I have seen in quite a few

examples of robes, which is interesting.

Norah Waugh’s pattern was also quite useful

in shaping the yoke.

This pattern was the most similar that we found to our

garment and was therefore very useful. We used the method of moving the two

parts the distance of the bottom ready to be pleated and this worked well.

With this there was a pattern for a hanging sleeve like the

one in the picture above. We have been looking mainly at medieval and Tudor

garments for inspiration with the gown. This is because the Mayors robe

originated from around this time as discovered in my research. I have seen a

few examples of robes in Hereford museum which are more similar to this one as

they have a T shape slit however the hanging sleeve is almost identical.

We had been trying to draw out the pattern for the sleeve

just using the measurements we had however because we knew no angles this was

almost impossible. We tried using equations to work out the angles of this

particular parallelogram until we found this. We applied our measurements to it

and removed the triangle off the top. This has worked very effectively. I feel

that had we had similar patterns to work from the process would have been more

accurate, for instance if we were making a garment inspired by a Janet Arnold

pattern.

Friday, 23 March 2012

Completing the toile and applying decoration

Over the last few days we have been getting the toile ready for the first fitting.

Below are some process photos showing the cartridge pleating on the back.

|

| Before stitching we drew a grid on the wrong side of the fabric. The vertical lines were 0.75cm apart and then 4 horizontal lines to space our stitching out evenly. |

|

| After folding the seam allowance under and adding wadding it was a bit hard to see our lines, especially on the CB seam. Therefore at points we had to add pins to make sure our pleats were even. |

|

| The reverse of the cartridge pleats after pulling them together. |

|

| Sewing the pleats to the design line on the bottom of the yoke. We pinned the centres together to make sure an even amount of fabric was on each side. |

|

| The completed cartridge pleats sewn to the yoke |

|

| The curve of the wing is too rounded because we are unable to sew the ribbon to it without making folds. We will need to adjust this line during fitting. |

|

| Decoration detail on the top sleeve and hanging sleeve. |

|

| Decoration detail |

|

| Finished hanging sleeve with ribbon along the bottom. |

Wednesday, 21 March 2012

Cartridge Pleating on Historic Garments

After

doing samples

we were unsure about the look and durability of our pleats. We decided to look

to historic images to see how closely they were packed and if you could see any

stitches when sewing them to a panel. Unfortunately because the bodices cover

all the pleats you cannot see how well they have been attached. I think I have

got a method now to sewing them and I am using double thread so I am sure they

will be strong enough.

On our samples there are lines where we’ve stitched and we

want to find out how to rectify this. On these examples however the pleats are

quite short and so I don’t think this would be a problem.

Monday, 19 March 2012

Cartridge Pleating

On the Mayor's robes 128cm worth of cloth is pleated into 32cm and then sewn to the yoke. I have been really excited to learn how to cartridge pleat because when you look at historic garments they so often have cartridge pleats on the waistline and so it is a valuable skill to learn.

Graham taught us that cartridge pleats are made by doing rows of running stitches that are an equal distance apart. When these are gathered you tie off the ends so they are tightly pleated. To make the pleats thicker we could experiment with wadding to bulk up the pleats.

To attach to the yoke you catch the edge of each pleat to he design line of the yoke. Each pleat will need 2 stitches to make it secure.

We calculated that 128cm of back fabric needs to be pleated onto 32cm of yoke. 128/32= 4. Therefore for every 1cm on the yoke we need to fit 4cm pleated in the back.

|

| 2cm stitches, no wadding |

We decided to experiment with different distances of stitches, with and without wadding.

Above is my first sample. Originally we had been told that to make a pleat so wide you need to do a running stitch double that width. So for instance a 1cm pleat would have 2cm wide stitches.

This wasnt the case however and to make a 1cm pleat the stitches need to be 1cm apart.

All my samples are using 40cm of fabric to be pleated into 10cm and therefore this sample was far too loose and thin.

|

| 1.5cm pleats with one layer of wadding. |

|

| 0.75cm pleats with one layer of wadding. |

Please see my workbook for samples

Sunday, 18 March 2012

Ede and Ravenscroft

Ede and Ravenscroft are a company probably best known in

today’s society as supplying academic gowns and hoods for graduation ceremonies.

They have, however, a long and fruitful history in making ceremonial and legal

gowns, owning the Royal

warrant as "Purveyors to the British Royal Family". They have supplied all

coronation robes for English monarchs since William and Mary in 1689, when they

were established, making them the oldest tailors in London!

It

was originally founded by the Shudall family, who were experienced tailors and

haberdashers and ran their business from Holywell street, an old London street that

lay where the Strand is today. In Victorian times Holywell Street was occupied “chiefly by old clothesmen and

the vendors of low publications” (Cunningham, P 1850) and demolished at

the end of the era but in the 17th century it was ‘the centre of the

tailoring trade, with many individual tradesmen working alongside one another

and combining their skills as the need arose (Campbell, U 1989) This

therefore was an optimum location for the business and enabled it to grow.

Willam and Martha Shudall tailored for

individuals mainly and a great deal of their clientele was involved in the

Church or the State. Their day book shows cassocks, gowns and coats being made

for clergymen and robes being made for knights of the Order of the Garter. In

this time coronation gowns were made and altered by the Shudall’s for the

coronations of the monarchy.

| King George III in his coronation robes in 1761. This robe is believed to be the oldest still in existence and is kept in the Royal Dress Collection at Kensington Palace. |

William died in 1757 and Martha retired in 1770,

leaving the business to a possible employee or partner Francis Stone. There

were no coronations in this time due to George III’s 60 year reign but he continued

to make robes for the knight. On his death in 1797 the business was left to

William Webb, who took on an apprentice, Joseph Ede, in 1811. Ede worked

successfully later becoming Webb’s foreman.

In 1827 Webb moved to Fleet Street After Williams

death in 1831his son succeeded and the company went into decline and was bought

by Ede’s uncle Thomas Adams. It was renamed Adams and Ede and in 1834 Joseph

Ede was appointed robemaker to His Majesty King William IV and later Queen

Victoria. Under his running the company grew in prosperity again. In 1837 with the change in monarchy Joseph

Ede would have got a lot of business, selling mourning bands and weepers to the

mourners of William IV as well as selling new coronation gowns, altering older

gowns and coronets for the coronation of Queen Victoria.

| Queen Victoria on her coronation in 1838 |

Ede’s son, Joseph Webb Ede, was appointed after

his parent’s death and the business became Ede & Son. In 1868 he was

appointed robemaker to Queen Victoria and moved from Fleet Street to Chancery

Lane, where the company remains today. In 1871 Josheph Ede married Rosanna

Ravenscroft, daughter of a successful wigmaker Burton Ravenscroft and the

joining of Ede and Ravenscroft was formed. The companies did not officially

merge until 1902, Joseph Ede died six months after their marriage and Rosa

continued his business with her brothers, her eldest brother Burton Ravenscroft

ran the wigmaking business and moved to a closer location.

Ravenscroft is a fascinating business in itself.

It was founded in a similar time of 1726, where wearing wigs was at the height

of fashion for men and women. The founder Thomas Ravenscroft sold his wigs to

the fashionable elite as well as the legal profession. Legal wigs were made of

black horsehair and needed to be curled and powdered almost daily and this

created a lot of business.

| Bar wig and Full bottomed wig made with white horsehair. |

Interestingly Humphrey Ravenscroft, grandson to

Thomas, developed a wig made of white horsehair which didn’t need curling and

powdering, called the forensic wig. He patented this in 1822 and it remains the

same today. He later adapted the full bottomed wig in a similar manner, so that

it did not need curling or powdering, in 1835.

The business remained in the Ravenscroft family

until the 1970s

The company continues to make the robes for the

monarchy, peers, parliament, court dress, clerical dress, civic dress and

academic dress with very little completion. Their catalogue and details can be

found here http://www.edeandravenscroft.co.uk/

I have really enjoyed finding out about Ede &

Ravenscroft’s history. Though it doesn’t really tell me anything towards

helping me make the gown accurately it is in an interesting part of social

history and demonstrates how such a successful tailors has been established.

On Wednesday Abi and I decided to email the ceremonial

specialist at Ede and Ravenscroft as we were really interested in the company

and seeing how they produce the gowns.

Dear Sir/Madam,

We are writting to enquire about the possibility of visiting Ede and Ravenscroft.

We are second year construction students on the BA (HONS) Costume with Performance Design course at the Arts University Collage at Bournemouth.

We are undertaking a project where we will create a replica of a traditional Mayor's Gown and are interested in learning more about how you make the gowns as a professional company.

Any help would be much appreciated and we look forward to hearing from you.

Yours Faithfully,

Abigail Booth and Katie Price

We are writting to enquire about the possibility of visiting Ede and Ravenscroft.

We are second year construction students on the BA (HONS) Costume with Performance Design course at the Arts University Collage at Bournemouth.

We are undertaking a project where we will create a replica of a traditional Mayor's Gown and are interested in learning more about how you make the gowns as a professional company.

Any help would be much appreciated and we look forward to hearing from you.

Yours Faithfully,

Abigail Booth and Katie Price

Unfortunately we were not able to visit. Though

this is disappointing it is understandable as they are the largest company of

this kind running. I appreciated the fast and polite response however and think

that it was worth us trying.

Dear Abigail and Katie,

Thank you for your email requesting a visit to our gown department.

Unfortunately, we will have to decline this request. As you will appreciate we do receive many requests and regrettably it is impossible to help everyone.

Thank you for your email requesting a visit to our gown department.

Unfortunately, we will have to decline this request. As you will appreciate we do receive many requests and regrettably it is impossible to help everyone.

However, I should like to take this opportunity to thank you for your interest in Ede and Ravenscroft and to wish you every success with your project.

Many thanks

Katherine

I would now like to find different places to

visit, possibly other manufacturers or tailors and I will be researching trying

to find a collection that has a good amount of civic robes. Though I know the

gown has hardly changed since its medieval origins it would be nice to find an

older example to look at to see how sewing techniques have altered.

Whilst researching Ede and Ravenscroft I found

that the company have kept a day book basically since they were founded. This

is held at the Guildhall Library in London and is something I would really like

to go and see as it would be interesting to find out about the kinds of fabrics

they use, the amount and the quantity by which they were being made at

different times.

Saturday, 17 March 2012

Costume Considerations

Mayor Chris Rochester

He considers the present robe too heavy for summer use and

so would like a lightweight robe that is breathable.

The robe is only really worn for ceremony and civic

occasions where it is worn with a jabot, lace cuffs and the Mayoral chains.

It is important to know what the robe would be used for and

so I have looked at the kind of duties the Mayor performs.

‘Except Members of the

Royal Family and HM Lord-Lieutenant of Dorset who represents same,

the Mayor takes precedence over all persons within the Borough - including

visiting Lord Mayors, Mayors and Town Mayors.

The Mayor is the First

Citizen of Bournemouth and represents the Council, all political groups and the

people of Bournemouth. He/she is a "public relations officer" for the

Town and MUST therefore be NON-POLITICAL AT ALL TIMES during his/her Term in

Office.

The Mayor, by virtue of the

Office, also presides at the meetings of the Council where it is his/her duty

to keep order and to carry out the procedure outlined in the Council's Standing

Orders. These set out the lengths of speeches, the procedure regarding the

rights of Chairmen of Committees in introducing their Minutes and their right

to reply at the conclusion of a debate, and the rules governing Motions.

In addition to Chairing the

Full Committee Meetings, held in the Council Chamber every six weeks, the Mayor

will:

§ open

a number of Conferences in the Town, extending Civic Welcomes and hosting Civic

Wine Receptions for their delegates;

§ open

various functions (school fêtes, new businesses and shops, etc.);

§ attend

a wide variety of events (Open Days, school/college presentations, Annual

General Meetings, Dinners, neighbouring Civic events, etc.);

§ entertain

a number of guests in the Mayor's Parlour at the Town Hall (foreign visitors,

Civic dignitaries, representatives of local organisations, etc.);

§ visit

many people (schools, rest homes, people celebrating their 100th birthday

or Golden Wedding Anniversary, etc.**).

Costume Considerations

The Mayor will not be wearing the robe for the majority of

these events and instead will just be wearing a medallion to show his position.

I do need to take into account however that a lot of people will see this robe

and so it needs to look professional, also people who meet him will see the

detailing of the robe and so these need to be of a high standard.

The robe will be photographed and so the fabrics I think

need to photograph well and the silhouette needs to be bold as well as the robe

being lightweight.

Some events where the robe will be worn will take place

outside and so we need to consider how the fabrics will react to weather. I

imagine the robe will not be getting particularly wet but I need to think about

how the fur etc. will react to water.

Price is another consideration, we have been given a budget

of £420 and so we need to stay within this, on the other hand the quality of

the fabric needs to be good to denote his superiority.

We will be handing over the garment before the ‘Mayor Making

ceremony’. This is held on the last Friday in May and this is where the Mayor

hands over to the next. The Sunday after this there is an annual civic service

where the new Mayor will process with their Civic Party, wearing full robes,

through the streets of Bournemouth to St Peter’s Church.

Constructing the Toile

By the end of week one we have started to put our pattern pieces together to make the toile.

We decided to quickly pin the garment together to gain a better understanding of how the pieces join and the shape that is created. To do this we roughly pleated the gathers on the back panel.

I am pleased with the overall look of the gown but I feel there are some inaccuracies to the original garment

The curves of the armhole are peculiar and we were aware of this when we drafted it. On the front panel, in order to get the side seam and CF the same as we had measured we had to make the armhole really shallow and this does not work when adding the sleeve. I am looking forward to seeing the shape of the sleeve in the original garment again to see how we went wrong, as I think this will help me learn a lot and progress with my pattern drafting skills in the future.

The curves of the armhole are peculiar and we were aware of this when we drafted it. On the front panel, in order to get the side seam and CF the same as we had measured we had to make the armhole really shallow and this does not work when adding the sleeve. I am looking forward to seeing the shape of the sleeve in the original garment again to see how we went wrong, as I think this will help me learn a lot and progress with my pattern drafting skills in the future.The front of the yoke sat a lot lower on the mannequin than it did on the Mayor. I think this is because of the difference in figure. On the Mayor the gown appeared to sit a lot higher on the shoulder because his chest and shoulders were broader. It is important to consider when fitting this garment that the client may be wearing a suit underneath and the shoulder pads and tailoring of the jacket will push the robe up, as demonstrated in the picture on the left. This will therefore mean the yoke will appear to be higher on the body.

It is great to see the sleeves fitting together after the confusion with pattern drafting!

It is great to see the sleeves fitting together after the confusion with pattern drafting! |

| Top-stitching sleeve to wing |

To sew the upper sleeve to the wing we top-stitched it into place as it is on the original gown

To sew the upper sleeve to the wing we top-stitched it into place as it is on the original gownAbi and I sewed a sleeve each and we both came out with slightly different curves when top-stitching the sleeve to the wing. This is another thing we need to double check on the original garment.

|

| Front view of sleeve |

I am pleased with how we have drafted the sleeves so far. There are elements that need adapting but I think we have got the overall appearance of the sleeve right.

|

| Back view of sleeve |

Subscribe to:

Comments (Atom)